The best Side of glass-lined glaze

The best Side of glass-lined glaze

Blog Article

Producing your Le Creuset cookware glimpse new requires a combination of cleansing, restoration, and correct treatment. In this article’s a phase-by-step tutorial to assist you accomplish a clean and revitalized look to your Le Creuset:

Enamels are like ceramic glazes, other than that, Whilst glazes are inside a Uncooked point out when applied to ceramics and endure chemical alterations in the firing approach that smelt them on to glass, enamels have presently been smelted.

Underglaze need to be allowed to dry fully involving coats in order to stop smearing or cracking once you hearth it from the kiln. For those who don’t allow sufficient time for drying among coats, it's possible you'll end up having an uneven complete on the piece.

Display screen With Pride: After your Le Creuset cookware is refreshed and revitalized, Display screen it with satisfaction as part of your kitchen or eating location. The renewed visual appearance will likely be a testomony towards your treatment and really like for these cherished kitchen area companions.

Reglazing your bathtub is a terrific way to take advantage of of the standard finishes now with your Area and lower your expenses as a way to splurge somewhere else (like on Individuals gorgeous sconces or plush bath towels you had your eye on). Most DIY bathtub refinishing kits Expense $40 to $a hundred and will reglaze tubs, sinks, toilets, tiled partitions, plus more.

Extensive Cleansing: Start out by supplying your cookware a thorough cleaning. Handwash it making use of gentle dish soap and warm water. Prevent working with severe abrasives or scouring pads which could destruction the enamel.

(1) weighing all the other parts except the refractory soil as well as water-based mostly varnish inside the formula on the glass-lined glaze content based on the proportion, putting the components into a material stirrer for stirring, whereby the stirring speed is 500r/min, the stirring time is one.5h, following stirring and mixing uniformly, carrying out glass lining firing and melting inside a muffle furnace to obtain a molten glass condition, whereby the glass lining firing and melting temperature is 1200 ℃ and the glass lining firing and melting time is 1.

Refinishing and reglazing your bathtub could sound like some thing much better still left to The professionals, nevertheless it's in fact doable to try and do all by yourself. Refinishing a tub ordinarily consists of utilizing a Do it yourself kit (available at lots of components suppliers) to reglaze an current enamel, acrylic, or fiberglass tub surface with a new tricky epoxy coating that could prolong its lifestyle and repair any compact challenges like minimal cracks or rust.

—so you'll need to buy Individuals individually. Other trusted kits on the market, such as ArmoGlaze and DWIL Tub & Tile Refinishing Package, have some of the resources you will need when you'd alternatively skip the additional vacation for the hardware retailer. A lot of kits also feature an etching powder (while the Rust-oleum a person does not). Etching powder isn't a required, nonetheless it may help you take away the outdated glaze far more quickly and absolutely, which can allow the new glaze to adhere greater. When your decided on kit will not come with etching powder, you can buy it independently.

Both equally components have their advantages: ceramic cookware is valued for its organic non-adhere Attributes and heat insulation, even though enamel-coated cookware offers sturdiness and resistance to chemical reactions with food items.

(one) weighing all the other parts other than the refractory soil and the drinking water-based mostly varnish inside the formula with the glass-lined glaze substance based on the proportion, putting the factors into a fabric stirrer for stirring, wherein the stirring velocity is 500r/min, the stirring time is one.5h, soon after stirring and mixing uniformly, carrying out glass lining firing and melting in a muffle furnace to get a molten glass state, whereby the glass lining firing and melting temperature is 1200 ℃ and the glass lining firing and melting time is 1.

Nonetheless, it’s essential to special enamel glaze Take note that thriving re-enameling requires some working experience with enameling tactics.

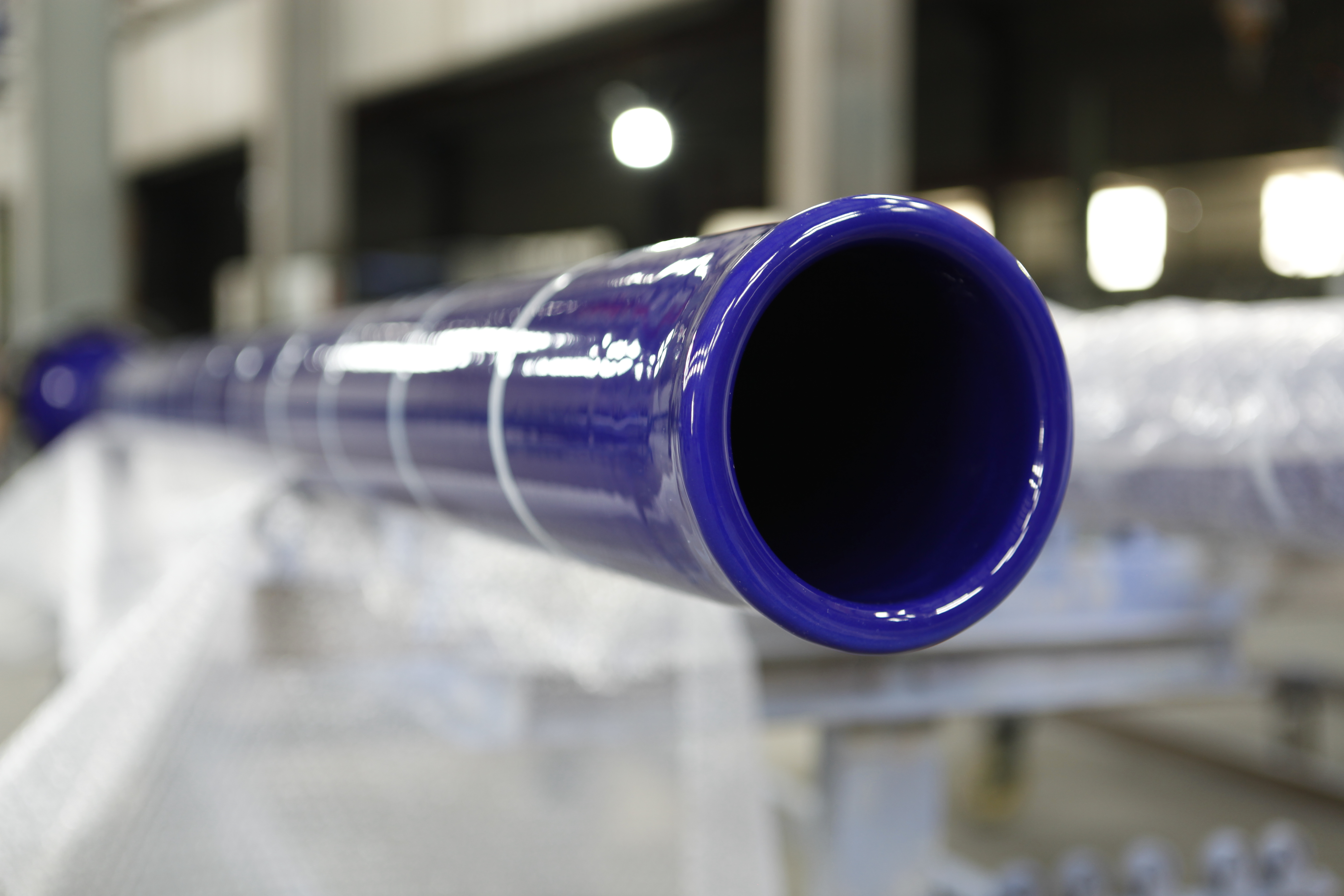

An anti-corrosion layer in an oil subject pipeline is prepared according to the glass-lined glaze materials proven while in the desk one, as well as steps are as follows:

A vitreous enameling method in which the enamel is utilized into cells manufactured from gold or silver wire, however there isn't any metallic backing. Using this method, mild can glow throughout the enamel and the piece contains a stained-glass result.